Peltier-effect / Thermoelectric cooling

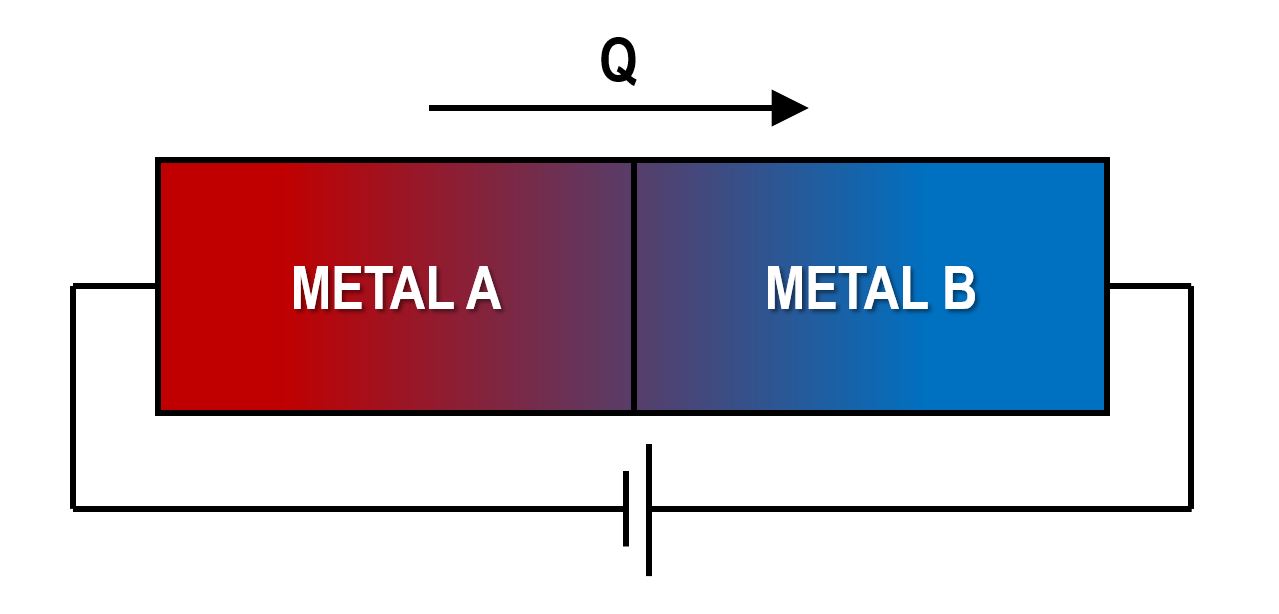

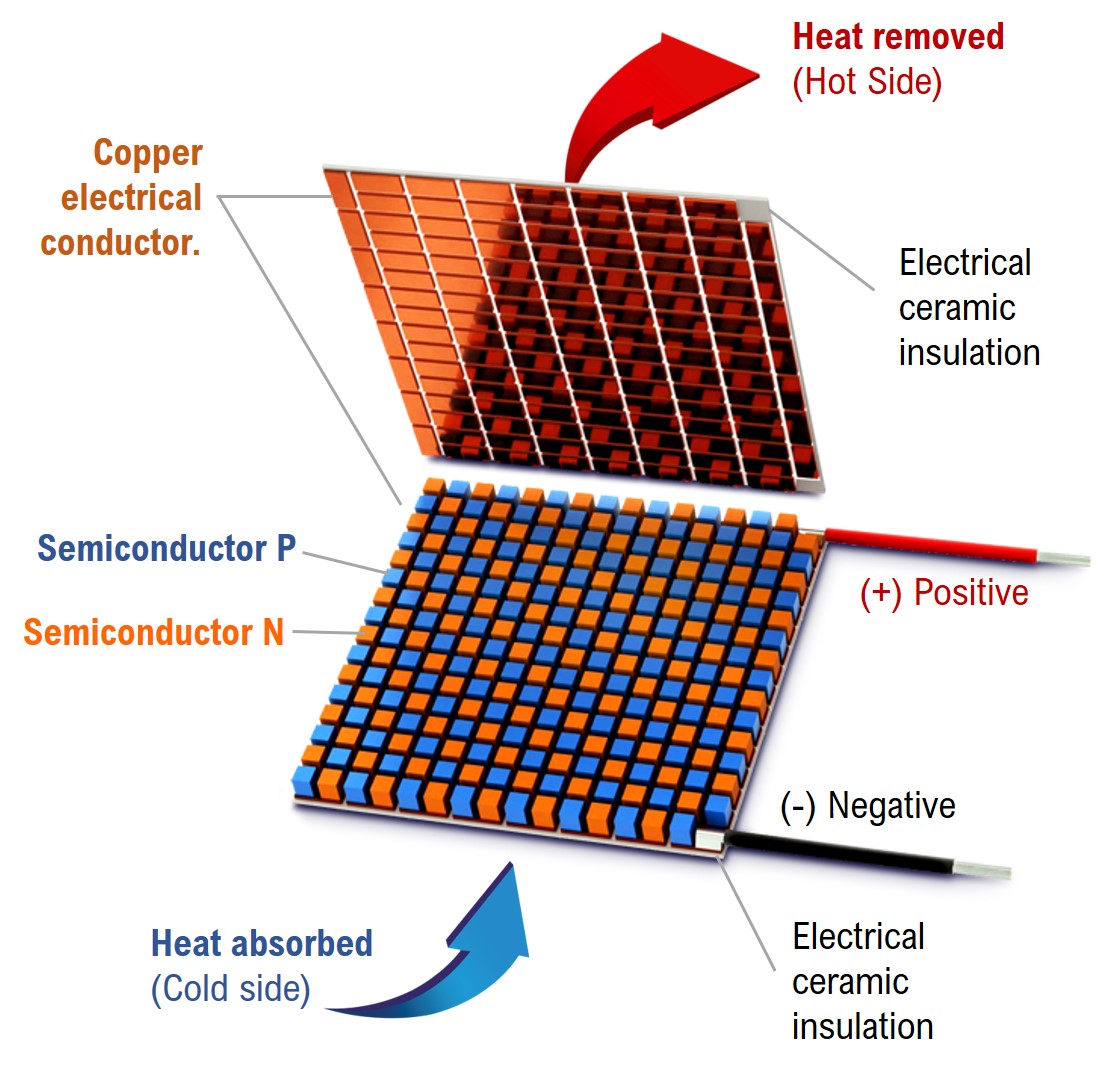

Peltier technology is based on the thermoelectric effect, or Peltier effect, and allows cooling and also heating, based on semiconductors and without the use of refrigerants. The heart of any Peltier device are the Peltier modules. When a DC voltage is applied, these generate a heat flow directed through the module, in other words a hot and a cold side are created on the module. If the heat generated on one side of the module is released into the environment, the cold generated on the opposite side of the module can be used technically.

By simply reversing the polarity, and thus changing the direction of the current, the hot and cold sides of a Peltier module also change. Thus it is possible to cool, heat or even temper with the same Peltier device.

Technical advantages

Due to the absence of coolants, results in a variety of technical advantages:

Resistance to difficult operating conditions, such as high ambient temperatures (+70 °C and above), vibrations, accelerations or changes in position.

Peltier control cabinet coolers also have further advantages, above all, as mentioned at the beginning, resistance to high temperatures, mechanical influences, but also to heavily polluted or salty ambient air.

Fields of application

One of the most important applications of Peltier technology is control cabinet cooling. Here, it mainly covers the range up to 300 watts cooling capacity. Conventional air conditioners, on the other hand, are only available from about 200 to 250 watts cooling capacity and are thus often oversized and/or too large for small cabinets and enclosures.

Lm-therm Elektrotechnik AG offers you an extensive portfolio of standard Peltier switch cabinet coolers between 30 W and 800 W power, which are usually available from stock. In addition, numerous accessories are available, such as top frames, condensate drain kits, controllers and thermostats, etc.

Peltier technology can also be used for cooling, or precise temperature control of liquids. Size, volume flow, material, flow direction and connections of the liquid cooler are thereby just as adaptable as cooling capacity, supply voltage, noise level, etc. of the overall system. This results in a multitude of possible applications as process cooling within production machines, in the chemical or food industry, etc.

individual adaptations

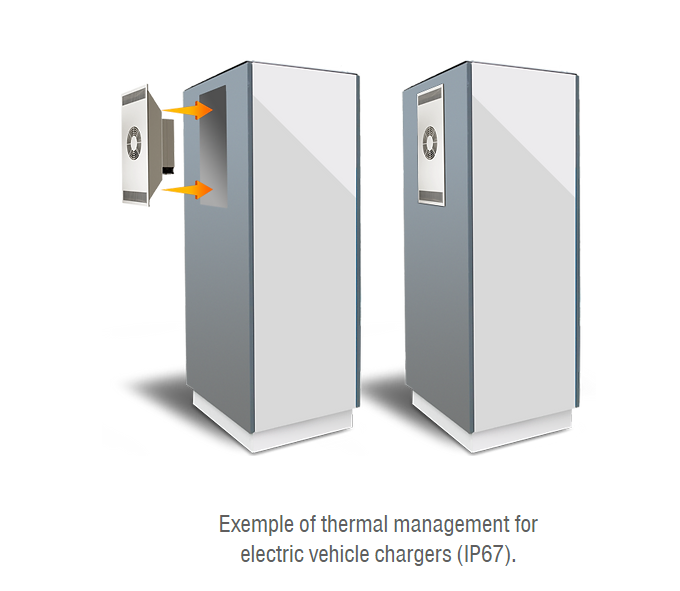

Due to the relatively simple design of Peltier devices, it is also possible to quickly and cost-effectively implement customer-specific adaptations or even completely new designs and applications. For example, performance, operating point, noise development, installation situation, sensor technology, operating voltage, air conduction or even the basic dimensions of the cooling unit can be optimized to suit its task. It is also possible, for example, to integrate a Peltier cooling unit into the control cabinet in such a way that it is located completely inside. The hot side is then ventilated through openings in the control cabinet wall. This also results in the possibility of designing the system to be vandal-proof, i.e., the unit is neither accessible nor removable from the outside.

Another example for the use of customized Peltier systems is the direct cooling of lasers or optical sensors. Since the waste heat from the systems to be cooled is emitted to a specific surface on the housing in this case, surface cooling is often used. This works more efficiently than air-to-air cooling systems and can be precisely adapted to the respective sensor or laser in terms of size, shape, mounting options, power or power supply.

Liquid-cooled or convection-recooled systems are also possible, e.g. when used in areas where freedom from vibration is required, when used in clean rooms or in, or on, machines with heavy chipping, for example in the wood industry.

The flexibility of Peltier technology results in many other applications and possible uses, such as in high-precision temperature control in laboratory and analysis technology, in aerospace technology, in the food industry, in thermal management of production processes, dehumidification of electrical equipment, and even air conditioning of transport containers.

Lm-therm Elektronik AG is your contact for all questions and applications in the field of thermal management and is your competent partner for the development and implementation of your project. We accompany you from the first problem analysis, over the prototype construction, up to the series production.

We look forward to working with you.