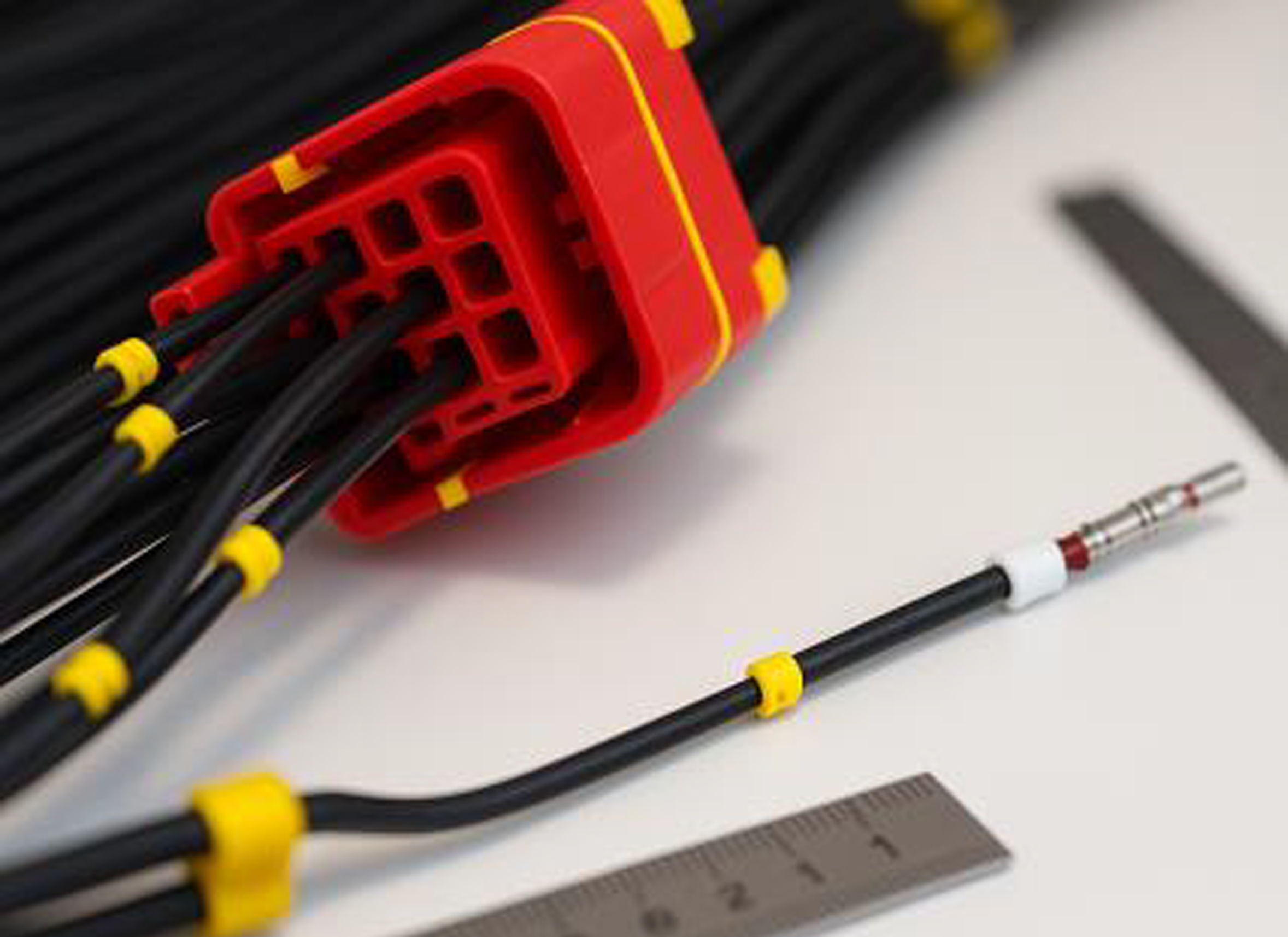

Reliable precision and quality in every connection – customized cable assembly for your requirements.

Are you looking for a reliable partner for the manufacture of customized cables, wires, and cable harnesses?

Our team, with over 30 years of experience, offers professional cable assembly services—from concept development and manufacturing to quality assurance. Using state-of-the-art technology and focusing on your individual requirements, we create connections that last.

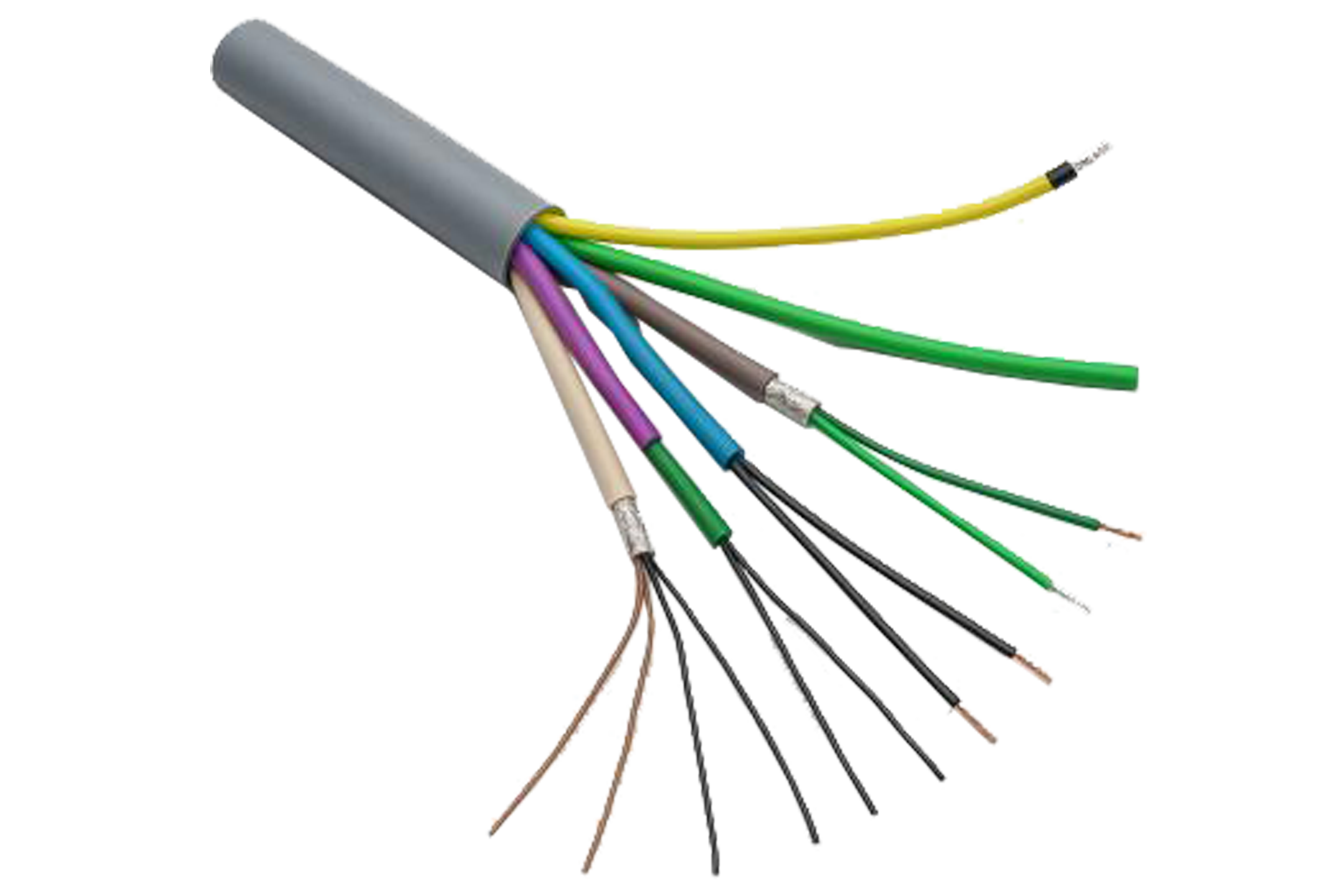

Examples of our services in the field of cable assembly:

Assembly of single-core and multi-core cables

Manufacture of cable harnesses & complete cable sets

Crimping, soldering, or tinning processes

Grounding cables & flat ribbon grounding cables

Our expertise and flexibility enable us to meet virtually any requirement.

- Partially and fully automated production: Efficient and precise manufacturing for any quantity.

- Manual production: Special and complex requirements, precisely implemented.

- Combination of technologies: Hybrid manufacturing processes that optimally combine manual and machine processes.

- Special requests: Such as custom cable lengths, special connectors, or markings.

Additional services:

- Various labeling options (automatic printing, labels, individual wire labeling)

- Assembly of parts provided by you. We only charge labor costs for this service.

- Production from batch size 1 to large production volumes

- Continuous quality assurance and customer-specific testing

Our process

- Consulting: Your requirements are our focus. We clarify all technical details and develop a concept.

- Prototyping: Before series production, we create a prototype to ensure functionality and accuracy of fit.

- Manufacturing: With state-of-the-art machinery and trained personnel, we guarantee the highest precision.

- Quality assurance: Every component is thoroughly tested before it leaves our premises.

Why us?

- Experience and expertise: Decades of experience in cable assembly.

- Quality standards: We work according to international standards and use only high-quality materials.

- Individual consultation: Our team works with you to develop the ideal solution.

- Flexibility: From small series to large production volumes.

Areas of application

- Mechanical engineering: Robust cable harnesses for industrial plants.

- Medical technology: Precise and secure connections for medical devices.

- Electrical engineering: Customized solutions for electronic devices and systems.

- Craftsmanship: Stranded wires and cables delivered ready for wiring.

Excerpt from our machine park

Komax Kappa 340

Image rights: Komax AG, Schweiz

Schleuninger E300

Image rights: Schleuninger Group, Schweiz

Your advantages through outsourcing cable assembly

- Cost reduction: Put your expensive specialists to work on the right tasks.

- Time savings: Focus on your core competencies and benefit from our short delivery times.

- Quality assurance: Professional expertise and modern technologies guarantee high-quality results.

- Increased flexibility: Lm-therm quickly implements individual requirements.

- Scalability: Flexibly adjust your needs to fluctuating order volumes.